首页 > PRODUCTS > SCREEN PRINTING SYSTEM > PRINTING MACHINETC-78 Servo Drive Automatic Cylinder Screen Press

TC-78 SERVO DRIVE AUTOMATIC CYLINDER SCREEN PRESS

INTRODUCTION:

MAIN SPECIFICATIONS:

The fully servo screen printing machine is a new generation of fully automatic screen printing machine independently developed by our company. It absorbs mature offset printing machine technology innovation and adopts an independent direct drive servo system, combined with high-precision heavy duty printing squeegee system and high-performance pneumatic side-lay structure.The maximum operating speed of the machine can reach 4500 sheets/hour. At the same time, it has many intelligent functions such as Gear disengagement function, printing patterm expansion compensation, and paper feeding time compensation, which greatly improve the efficiency of the printing machine. This machine is suitable for screen printing in ceramic or glass transfer printing, advertising, packaging printing, signage, textile transfer printing, and electronic industries printing etc.

MAIN SPECIFICATIONS:

|

Model |

TC-78 |

|

Max. material size |

540x780mm |

|

Min. material size |

310x350mm |

|

Screen frame size |

940x940mm |

|

Printing speed |

500-4500pcs/h |

|

Gas specifications |

225L/min 5-7kgs/cm² |

|

Power |

3P 380V 50Hz 17kw |

|

Weight |

3000kg |

|

Dimension |

3230x2640x1700mm |

MAIN FEATURES:

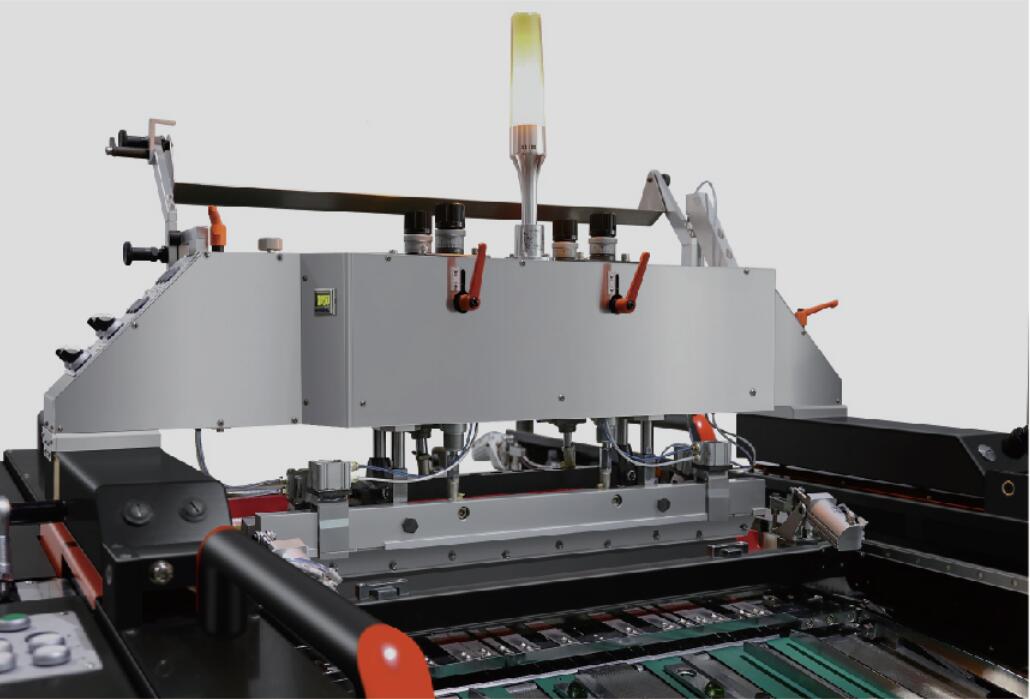

1. The squeegee bridge swings up from print level into the raised position as well as the screen carrier, easy for replace.

2. Anti-static aluminum plating feed can also install anti-scratch velvet to prevent surface scratches damaged;vacuum suction conveyor system, effectively reduce the number of transmit pressure wheel to avoid scratching and greatly shorten the adjustment time of feeding.

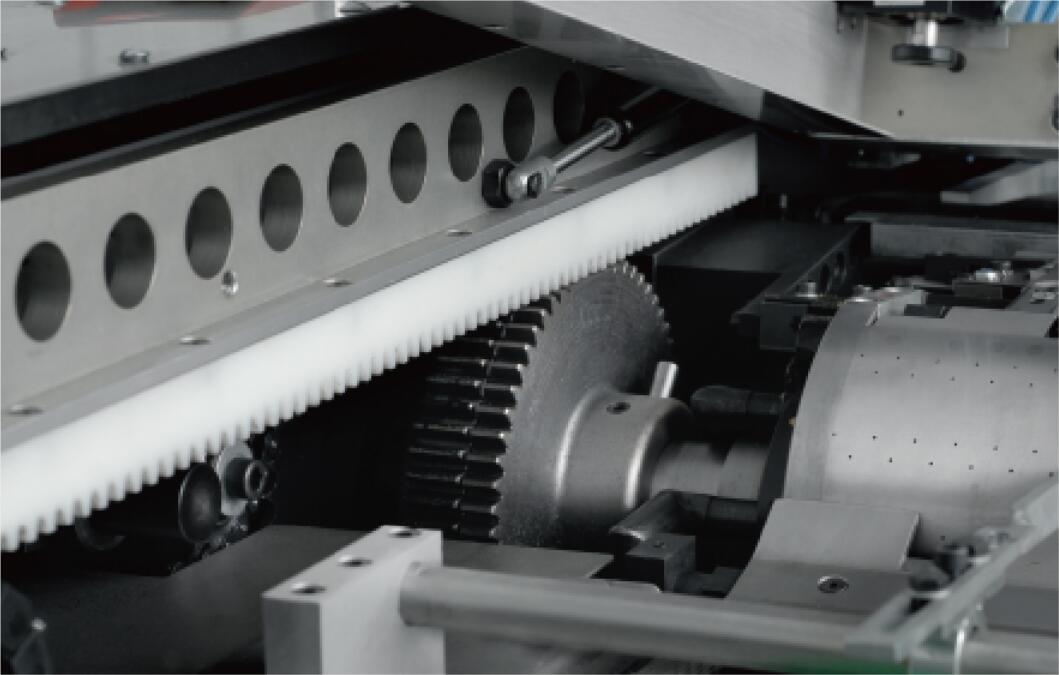

3. Automatic rack disengagement function: the mesh rack can be disengaged from the gear automatically. There is no need to calibrate the version again to view and adjust the paper feeding condition, which greatly improves the efficiency and saves time.

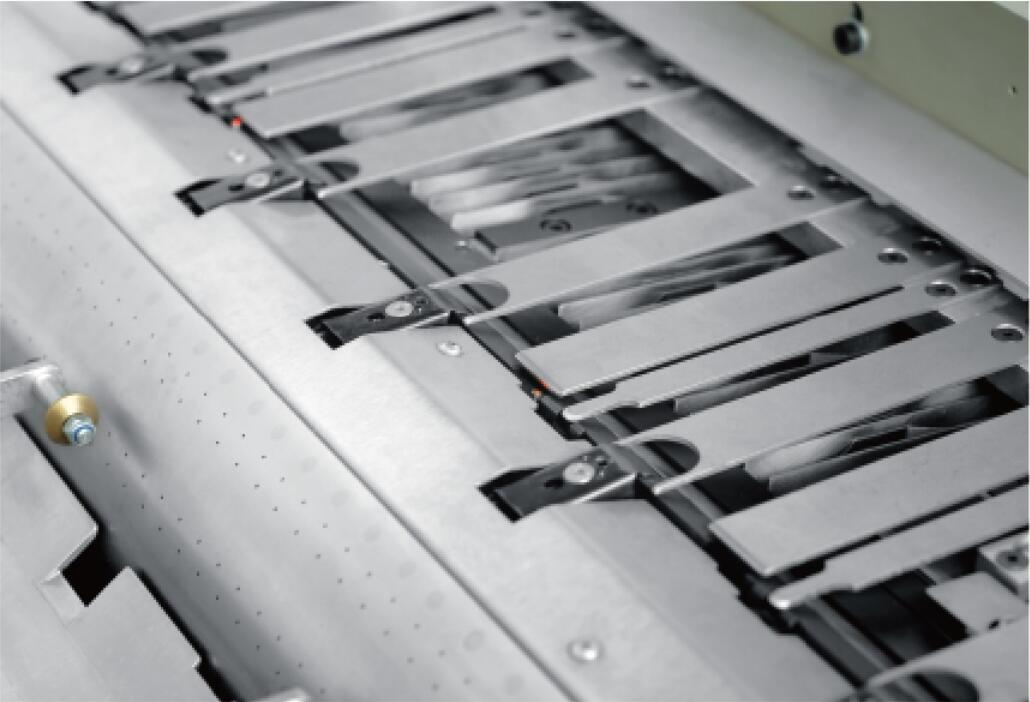

4. Heavy-duty precision scraper system, the integrated use of electronic, pneumatic, hydraulic, mechanical, optical fiber and other advanced technology, the knif e pressure can be preset to control the knife position, the squeegee pressure calibration, ie, remains constant to ensure precise control of ink thickness, to ensure perfect and consistent printed product.

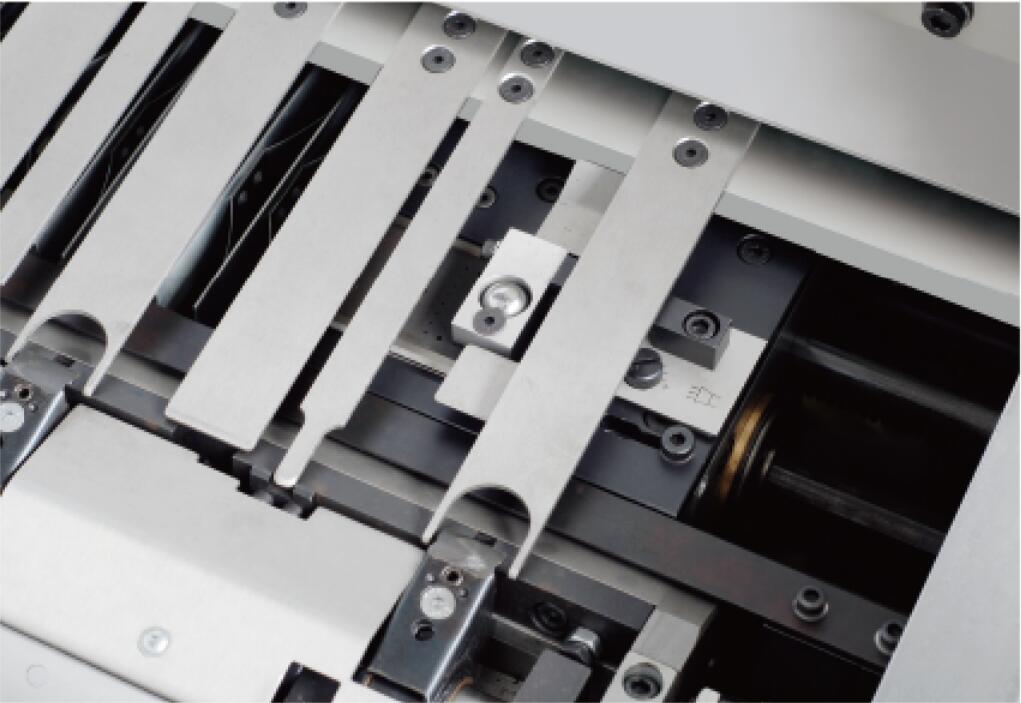

5. Vacuum side lay system, with side lay sensors to align, ensure the location accurate and stable, at the same avoid to make the trace of the pull location.

6. Unique cylinder groove design, making the screen frame adjustable distance close to zero, achieve the little distortion of screen frame, en-sure the accuracy of the printed pattern.

Copyright © 2012 SHM INTERNATIONAL 沪ICP备12034060号-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356