TC-106C SERVO CONTROL SCREEN PRINTING MACHINE

INTRODUCTION:

TC-106C Intelligent servo automatic screen printing machine is a new intelligent screen printing machine independently developed and designed by our company, which has completely independent intellectual property rights. It is an industry-leading product with a number of invention patents and utility model patents. Under the requirement of ensuring the quality of printed products, the full-size printing speed can reach 4500 pieces/hour. If you choose to print personalized products, the speed can reach 5000 pieces/hour. It is the best choice for today's paper and plastic boutique packaging, ceramics and glass decals, textile transfer, plastic film switches, electronic and electrical related components and other industries.

The machine abandons the traditional single power source with transmission shaft, gearbox, chain and crank, and then drives the four moving bodies of Feida, conveying, roller and mesh frame. Use servo motors to drive the paper feeding conveying, roller and frame respectively. Through automatic control, the synchronization of several functional units is ensured, which not only eliminates alarge number of mechanical transmission parts, but also greatly improves the stiffness of printing machinery, It reduces the error caused by the mechanical transmission device, improves the printing qualityand mechanical efficiency, improves the automation level of the production process, and improves the working conditions of the environment.

The devices can have their own starting point and independent speed because of the seperation design. By adjusting the control data of each device, it is easy to realize different running tracks and running states, realizing the flexible production of the full-automatic drum sheet fed screen printing machine.

MAIN FEATURES:

1. Full servo/Shaftless transmission

The flexible application ensure that the equipment can adapt to different properties and specifications of materials and inks faster and better during operation, solve problems that arise during production faster, solve various faults faster, ensure production efficiency, and complete production with higher production capacity, better products, lower energy consumption, and scrap rate.

(1) Short route operation of screen printing: By changing the route data of the printing plate, the movement stroke of the screen printing can be easily changed. For small area products, it can effectively extend the service life rthe screen printing and improve the printing speed while ensuring the printing effect;

(2) Large proportion of printing and ink flood speed ratio: there is one ink flood action and one printing action in a cycle of screen printing. By setting different speed ratios, productivity can be improved on the premise of ensuring printing effect; Especially for high penetration inks, a high ink return speed can effectively reduce the pattern deformation and ink shedding caused by ink penetration after ink return. A low printing speed can also improve the printing effect;

(3) Significantly shifting the pattern back and forth: By modifying the starting point of the frame servo, it is possible to quickly solve the problem of error border position during exposuring, or to quickly achieve the completion of paper direction alignment through data changes during glignment;

(4) Scaling of printing patterns: By modifying the data, the 1:1 drum to frame speed ratio is slightly changed, changing the original 1:1 printing pattern to 1:0.99 or 1:1.01, etc., in order to compensate for the shrinkage deformation of the paper during process conversion and storage, as well as the pattern stretching deformation caused by insufficient screen tension;

(5) Adjustment of paper feeding time: By adjusting the original point data of the Feida motor, the material conveying time is modified to quickly achieve the delivery time of special materials to the front side gauge, ensuring the stability and accuracy of paper feeding;

(6) The multi-stage transmission mechanism is reduced, and after the transmission rigidity is improved, the servo transmission system can change the speed faster, reduce the machine adjustment time, and reduce the machine speed up and down cycle, thus greatly reducing the overprint waste caused by different screen deformations at high and low speeds of screen printing, reducing the waste rate, and improving the efficiency;

(7) Multiple power transmission systems, each equipped with temperature monitoring and fault display, can provide early warning in case of transmission system failure; After the transmission is independent, the fault point can be quickly located through the transmission system alarm;

(8) Multi axis servo transmission and energy-saving technology are adopted for energy recovery and reuse. At the same speed, the servo model saves 40-55% energy compared to the mechanical transmission type main transmission system, and during normal printing, it saves 11-20% energy;

(9) The step by step adjustment system can achieve a one click version change function: reducing the equipment adjustment time required for changing material specifications from 5-10 minutes to 2-5 minutes, reducing work order switching time;

(10) Built in scrap removal function, connected to the paper receiving unit, detects paper that is not in place or missing printing due to improper cutting, and promptly removes it to prevent waste and missing printing materials from flowing into the paper receiving device.

For the existing conventional full-automatic screen printing machine can only be realized by remaking the screen, using multiple locks to adjust the screen, adjusting the angle of the mechanical sprocket, etc., which is time-consuming, laborious, and greatly increases the cost, while the short stroke and large speed ratio can not be realized by mechanical transmission.

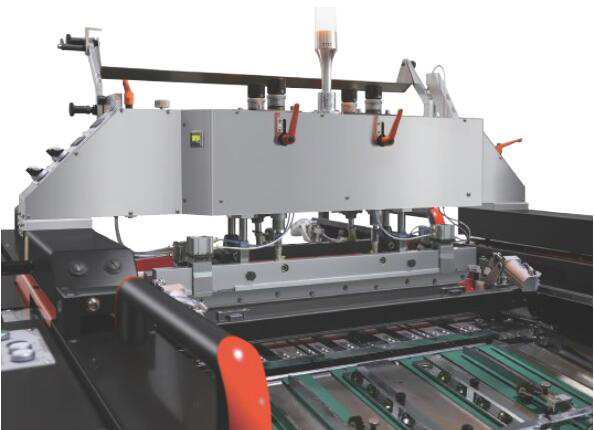

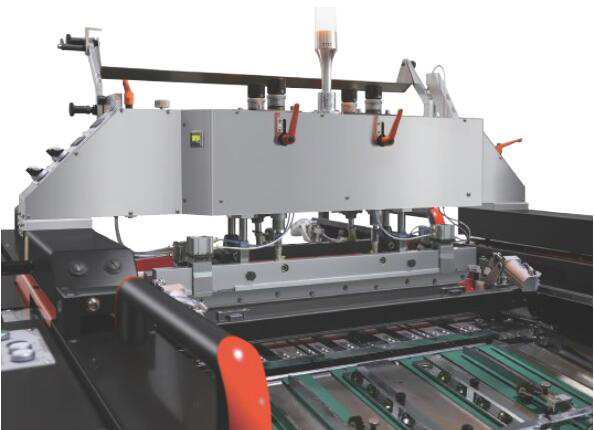

2. Pneumatic scraping system

(1)New pneumatic ink scraper system

The scraper system of the traditional Cylinder screen printing machine is controlled by the cam.

When the equipment screen frame moves to the front and rear positions, the scraper and ink return plate controlled by the cam have a switching action. However, with the continuous improvement of the running speed of the equipment, the defects of this system become obvious. When the scraper switches, the downward movement of the doctor blade will impact the mesh. If it scrapes the upper surface of the roller teeth under the mesh, it is easy to damage the screen; When the equipment runs at a high speed, it will also cause the instability of the paper positioning before printing; In addition, the most serious problem is that at high speed, when the scraper cam controls the fall and switches, there will inevitably be a slight vibration. The performance of screen printing and printing patterns is the instability of graphics and text, which is commonly known as knife jumping.

In response to the above problems, Jinbao Company has innovatively introduced a Hydraulic and Pneumatic scraper bridge, which has skillfully overcome the technical difficulties that have plagued the screen printing industry for many years.

The Scraper bridge system maintains synchronous motion with the Cylinder/Frame, but there is no mechanical connection between them. The rubber scraper cross bridge system uses air pressure to control the lifting of the scraper, and hydraulic control to buffer in place to ensure that the rubber scraper pressure is accurate, stable, and always constant. The switching action fully matches the cylinder speed, and the starting and ending points (switching position points) of printing can be adjusted.

*During printing test, the earliest National Standard of silk screen printing machine stipulates that the printing non-uniformity is not more than 25%, and the ink application instability is not more than 0.12mm; The National Standard of version 04 and 13 stipulates that the printed matter shall have uniform ink color, clear lines and visual inspection. There is no national standard for roller screen printing machine, and the industrial standard JB/T 9124.2 is equivalent to the national standard.

According to the National Standard of Offset Press, the printing non-uniformity is not more than 15%, and the ink application instability is not more than 0.04mm;

*Ink layer unevenness: the evenness of each ink layer of the field pattern after printing on the same sheet of paper; It reflects the ability to ensure the printing effect/pressure in the whole printing format when the same sample is printed;

*Ink application instability: the stability of the inking layer of different sheets in the same color block at the same speed; It reflects the ability to ensure the printing effect/pressure of different proofs before and after the long-term printing process;

(2)Same screen printing test

At the speed of 2000-4000, the non-uniformity data of pneumatic scraper is basically below 5%,

At the speed of 2000-3500, the nonuniformity data of mechanical scraper type fluctuates by 5%-15%. When it is higher than 3500, the nonuniformity data of mechanical scraper type exceeds 25%, sometime the margin edge even shows the misprint caused by the mechanical scraper's jummping problem.

Ink application instability data, the test results below 0.08mm can still be guaranteed when the speed of the pneumatic scraper is up to 4000; The general standard requires that 75% of the maximum speed, that is, 3200 or so, can reach the standard;

The mechanical scraper type equipment can only reach the test result of 0.11mm at 3200 and below, and the instability data continues to increase with the speed continues to accelerate.

After March 2023, the switching control of the printing blade are changed from cylinder to servo motor, increase the printing pressure and meet the needs of screen printing with less permeable inks, such as ceramic decal inks and high viscosity self drying color inks. The basic structural form of the pneumatic knife remains unchanged.

(3)Partical features

Paper feeding Feeder

Offset Feeder head, higher speed, reliability and stability.

It has strong adaptability to the thickness of printed parts, and ensures smooth paper feeding at high speed. The paper feeder can choose by itself and switch single sheet or laminated paper by one button.

Paper feeding table

The stainless steel paper feeding table can effectively prevent the back of substrate from being scratched, and reduce the static friction between the table and substrate;

With vacuum adsorption at the bottom of the table, with the structure of pushing paper and pressing paper on the table, to ensure the smooth transportation of various materials;

When a single sheet of paper is fed, the conveyor belt slows down at the right time to ensure that the substrate is stable and in place at high speed.

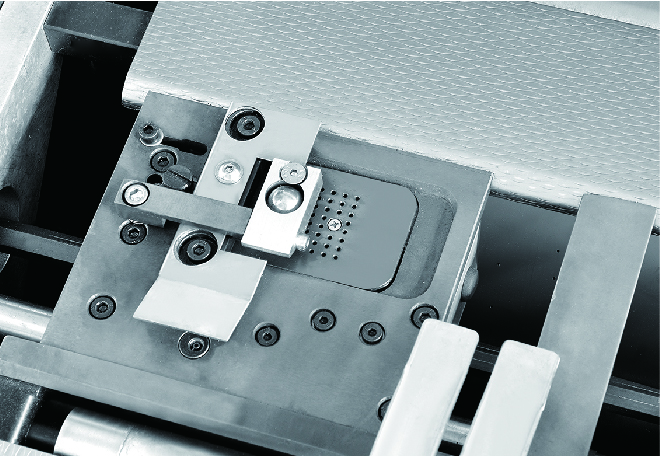

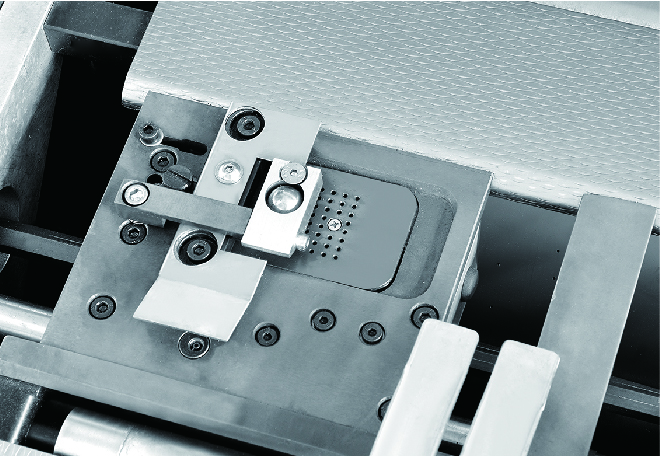

Pneumatic side gauge

The downward suction vacuum side pull gauge will not cause white and dirty paper and text marks;

One body variable push gauge type, one key switch, start and control push gauge pull gauge conversion;

Push pull positioning is accurate, positioning stroke is long, positioning speed is fast, and adjustment is convenient. The photoelectric detection system can monitor the position of printed parts in real time and reduce the rate of printing waste.

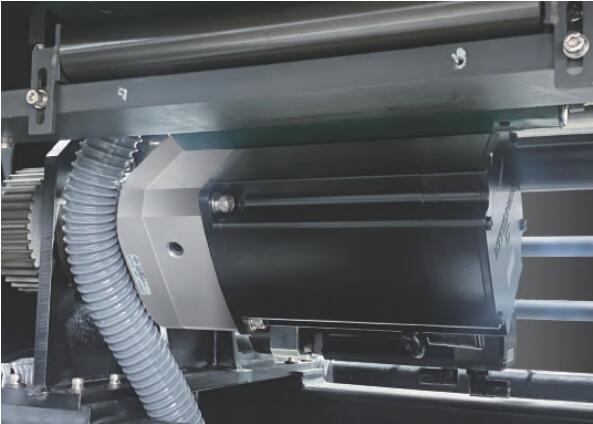

Shaftless system

Traditional single power source of main drive with multiple drive modes

Using synchronous drive technology, the transmission shaft, gearbox and other mechanical devices are removed, and multiple servo motors are used to follow the virtual electronic spindle. A large number of mechanical transmission parts have been eliminated.

Noise reduction: the traditional main shaft and gearbox are discarded, the moving parts are reduced, the mechanical structure is simplified, and the components generating mechanical vibration are reduced, so the noise is greatly reduced in the operation process.

Heavy pneumatic scraping system:

Comprehensive application of electrical, pneumatic, hydraulic technology, automatic control of scraping action;

Start and end points can be set independently;

The whole process pressure is balanced and stable;

It completely eliminates the disadvantages of cam mechanical control of squeegee action, and ensures that the ink layer and clarity of the image are stable under any printing volume and printing speed.

Screen separation function

The screen is separated by electric control to expose the whole conveying table and roller, so as to facilitate the registration of printing parts and the adjustment of feeding materials; at the same time, the cleaning of roller and screen is safer and faster;

Automatic oiling and lubricating system

MAIN SPECIFICATIONS:

|

Max sheet size |

1060x760mm |

|

Min sheet size |

560x350mm |

|

Max printing size |

1050x750mm |

|

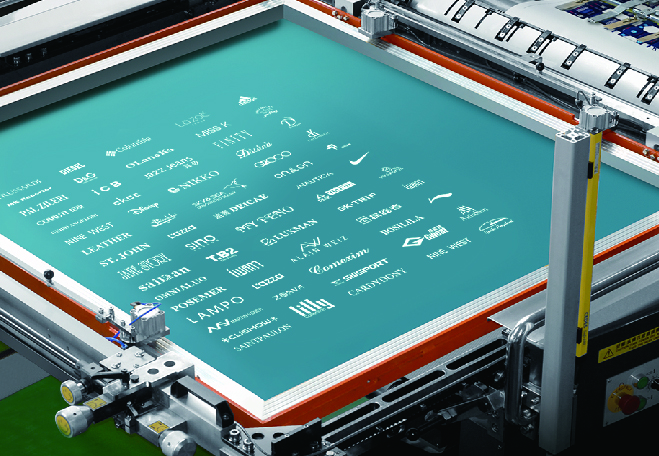

Frame size |

1300x1170mm |

|

Sheet thickness |

90-500gsm |

|

Pile height |

90cm |

|

Border |

≤10mm |

|

Printing speed |

500-4500 PCH |

|

Power required |

3P 380V 50Hz 38.53kw |

|

Weight |

4600kg |

|

Dimension |

4850x4220x2050mm |

PNEUMATIC SIDE-LAYPneumatic side-lay

The downward vaccum suction side guide will not cause discoloration,dirty on the paper surface or graphics and text surface;Integrated pull and push side guide,one button switch,start switch from pull to push;Accruate push and pull positioning, long positioning stroke,fast positioning speed and convenient adjustment;The photoelectric detection system monitors the real-time status or printed sheets,reduces the waste rate of printing.

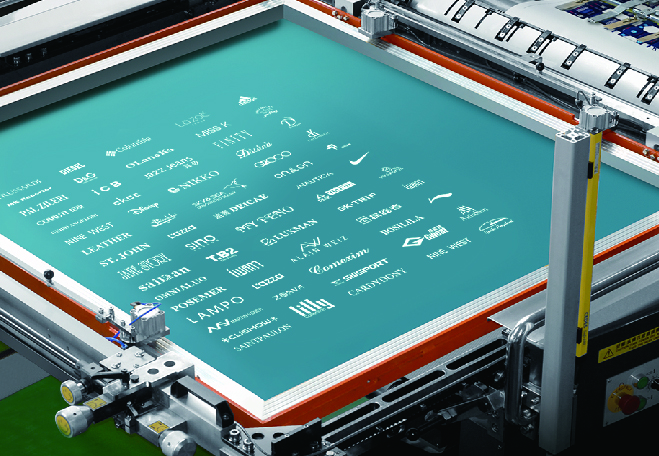

SEPARATED SCREEN FRAME STRUCTURE

The electrically controlled screen frame structure detaches,exposing the entire conveying delivery board and cylinder,convenient for alignment of printing sheets and the adjustment of feeding; and more faster and safter for cleaning the cylinder and frame.

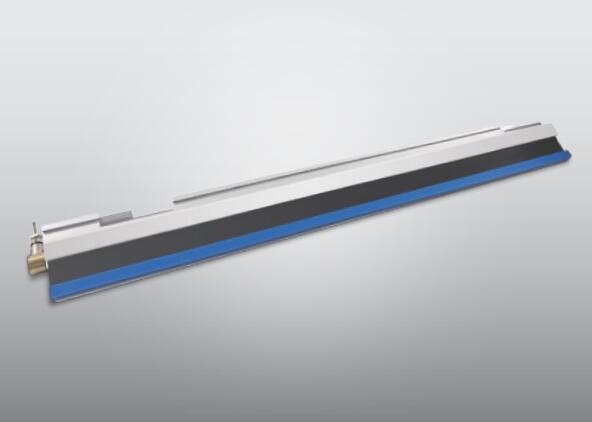

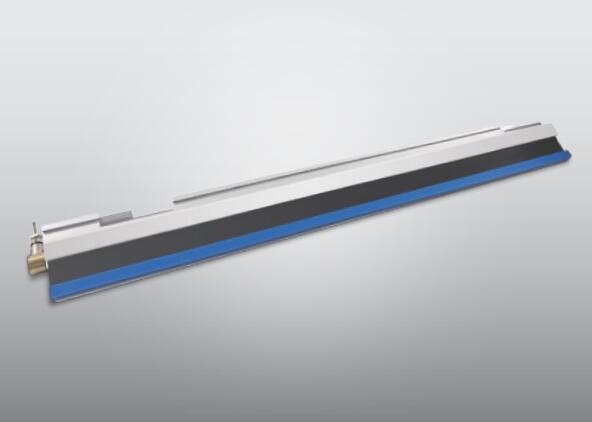

CARBON FIBER SILK SCREEN SCRAPER

Super standardized printing quality; regenerated repeat required quality; the best flatness surface of scraper, makes the inklayer stable and settle fast; excellent solvent resistance and abrasion resistance, extending the life of scraper and consumables.

SUPER-PRECISION PNEUMATIC SQUEEGEE SYSTEM

Heavty duty pneumatic&electric squeegee bridge system:comprehensive application of electrical, pneumatic, and hydraulic technologies, automatic control of squeegee actions.The print starting and ending points can be set independently;Equalled and Stable pressure throughout the whole process;Completely eliminating the drawbacks of cam mechanical control of squeegee actions,ensuring that the ink layer and clarity of the image remain stable regardless of any printing volume and speed.

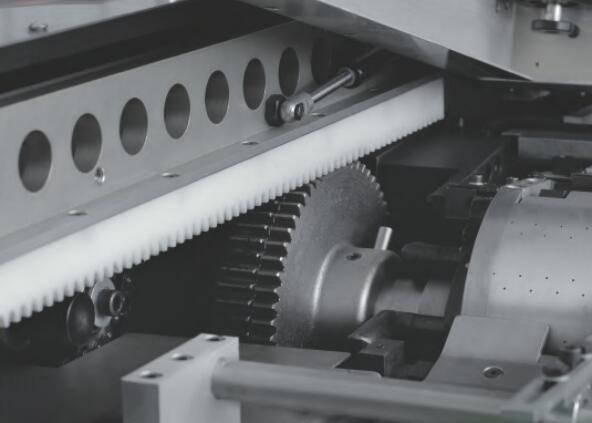

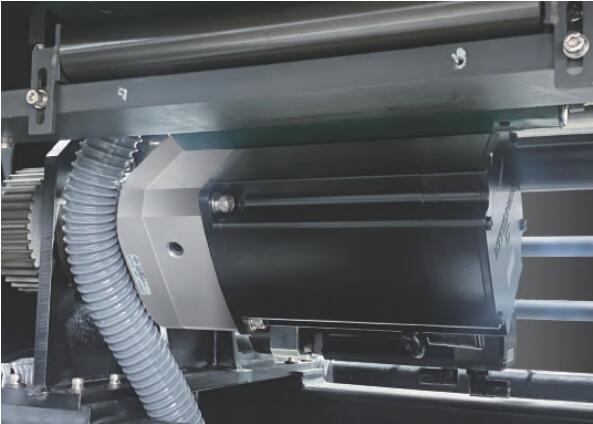

SHAFTLESS TRANSMISSION SYSTEM

Using servo synchronous drive technology, remove mechanical devices such as transmission shafts and gearbox , and use multiple servo motors to follow the virtual electronic spindle movement. Eliminated a large number of mechanical transmission components, simplified the mechanical structure, and reduced mechanical vibration; Improved smoothness and speed of movement.

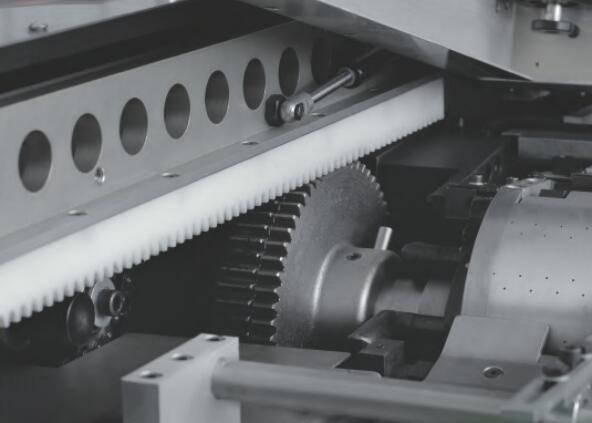

Nylon Rack

Screen plate and cylinder runningin-phase, with the combination of nylon rackand steel gear drive, ensure the running gear and rackno space and no vibration, to ensure overprint accurate, low wear, prolong the service life of equipment.