Ê×Ò³ > PRODUCTS > SCREEN PRINTING SYSTEM > PRINTING MACHINETC-54C Servo Control Screen Printing Machine

TC-54C SERVO CONTROL SCREEN PRINTING MACHINE

INTRODUCTION:

JB-54C is a complete new designed machine developed by us with 3 patents for invention, 5 patents for utility models. Running at full sheet size with quality guaranteed, top speed can reach 4500s/h. It is an unique machine for packaging printing, decal printing, textile and legend printing. For further information, please contact us or local sales representative.

MAIN SPECIFICATIONS:

| Model | TC-54C |

| Max sheet size | 550x400mm |

| Min sheet size | 290x210mm |

| Max printing size | 540x390mm |

| Screen frame size | 700x700mm |

| Sheet thickness | 90-500gsm |

| Border | ≤10mm |

| Printing speed | 500-4500 PCH |

| Power required | 3P 380V 50Hz 38.53kw |

| Weight | 2170kg |

| Dimension | 2800x1400x1600mm |

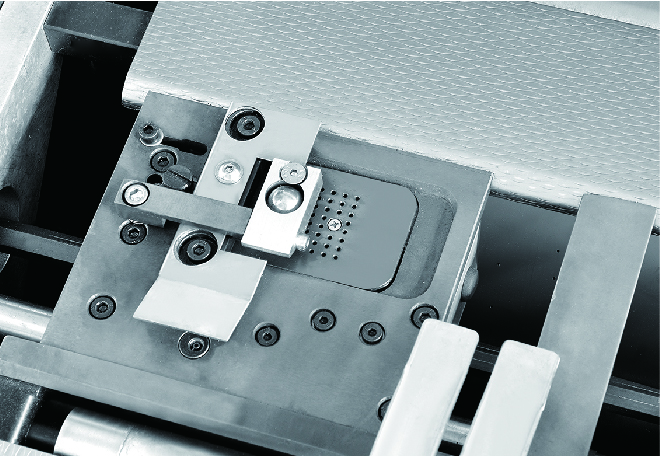

The downward vaccum suction side guide will not cause discoloration,dirty on the paper surface or graphics and text surface;Integrated pull and push side guide,one button switch,start switch from pull to push;Accruate push and pull positioning, long positioning stroke,fast positioning speed and convenient adjustment;The photoelectric detection system monitors the real-time status or printed sheets,reduces the waste rate of printing.

SEPARATED SCREEN FRAME STRUCTURE

The electrically controlled screen frame structure detaches,exposing the entire conveying delivery board and cylinder,convenient for alignment of printing sheets and the adjustment of feeding; and more faster and safter for cleaning the cylinder and frame.

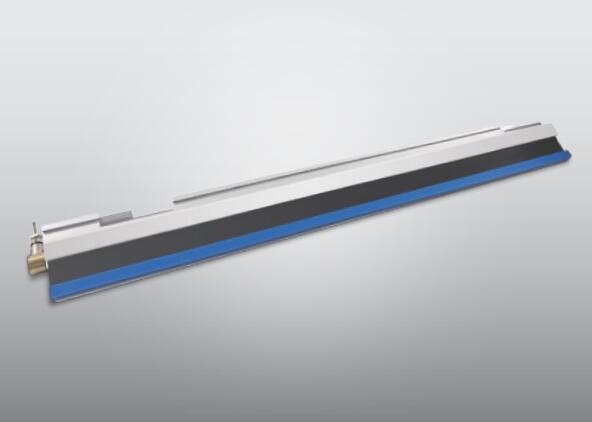

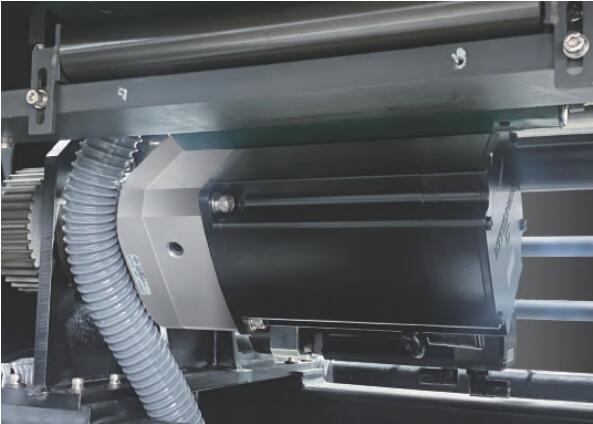

CARBON FIBER SILK SCREEN SCRAPER

Super standardized printing quality; regenerated repeat required quality; the best flatness surface of scraper, makes the inklayer stable and settle fast; excellent solvent resistance and abrasion resistance, extending the life of scraper and consumables.

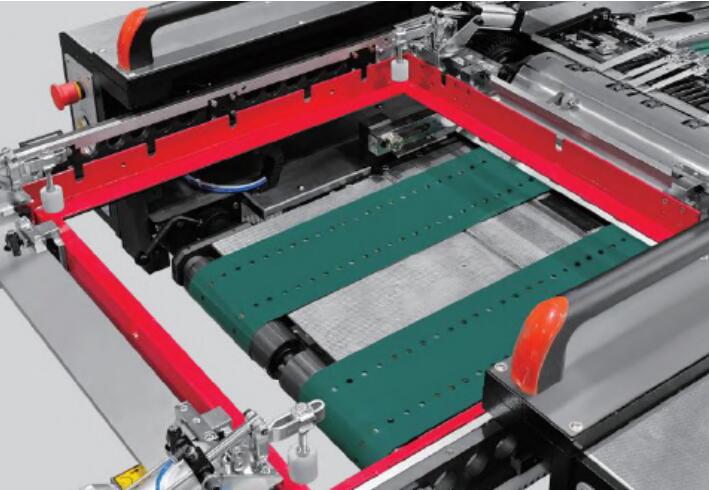

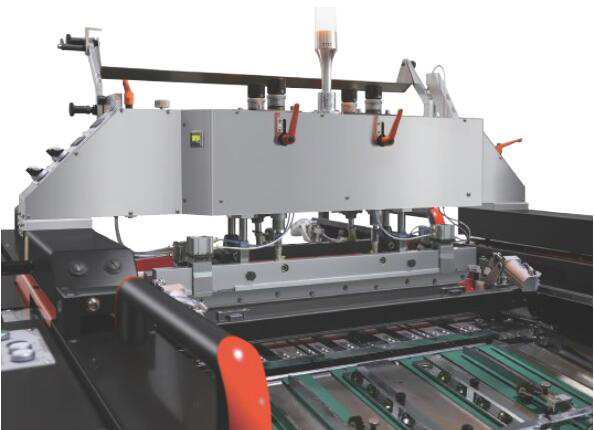

SUPER-PRECISION PNEUMATIC SQUEEGEE SYSTEM

Heavty duty pneumatic&electric squeegee bridge system:comprehensive application of electrical, pneumatic, and hydraulic technologies, automatic control of squeegee actions.The print starting and ending points can be set independently;Equalled and Stable pressure throughout the whole process;Completely eliminating the drawbacks of cam mechanical control of squeegee actions,ensuring that the ink layer and clarity of the image remain stable regardless of any printing volume and speed.

SHAFTLESS TRANSMISSION SYSTEM

Using servo synchronous drive technology, remove mechanical devices such as transmission shafts and gearbox , and use multiple servo motors to follow the virtual electronic spindle movement. Eliminated a large number of mechanical transmission components, simplified the mechanical structure, and reduced mechanical vibration; Improved smoothness and speed of movement.

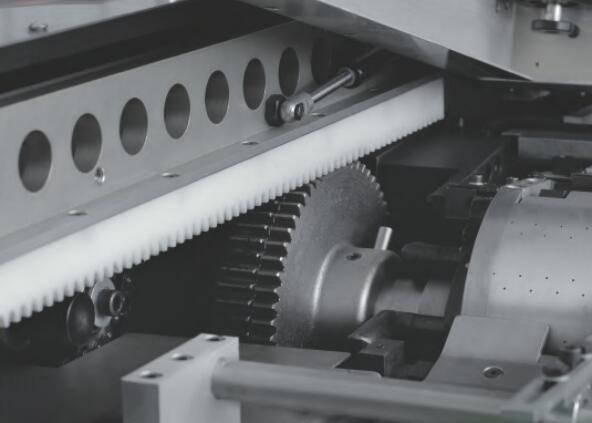

Nylon Rack

Screen plate and cylinder runningin-phase, with the combination of nylon rackand steel gear drive, ensure the running gear and rackno space and no vibration, to ensure overprint accurate, low wear, prolong the service life of equipment.

Copyright © 2012 SHM INTERNATIONAL »¦ICP±¸12034060ºÅ-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356