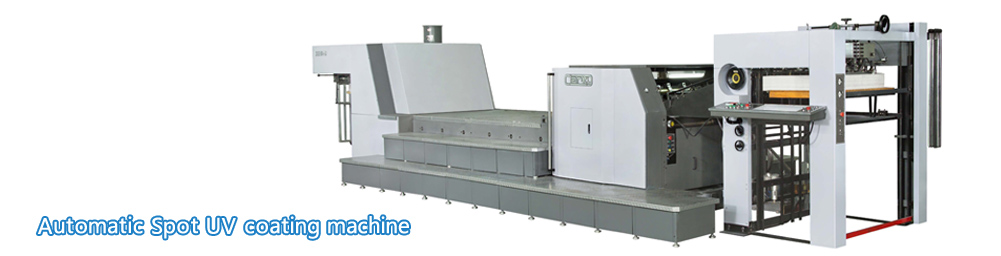

HOME > PRODUCTS > POSTPRESS SYSTEM > UV COATING MACHINEDG104UV High Speed Spot UV Coating Machine (TC)

DG104UV High Speed Spot UV Coating Machine

MAIN FEATURES:

1. Reasonable combination of well-designed front guide, pulling guide and swing-down sheet transfer mechanism.

2.Swing-down sheet transfer mechanism can shake foreign materials out on the surface of printed matter to allow the luster surface bight and smooth.

3.Swing control of sheet transfer with conjugate cam reduces vibration noise and makes working environment silent.

4.Fold diameter impression cylinder reduces press effect caused by surface tension of the lustering oil, decreases orange peel, improves brightness of the printed matters and suits for lustering for thick and thin paperboard and sheet.

5.Cavity scraping ink knife, the type of internal storage light oil with external isolation, avoid the light oil spills, high precision roller oil supply, glazing oil uniformity and flat, and can effectively control the amount of oil.

6.Quick exchange device of anilox roller, quickly exchange anilox roller with different lines as different glazing requirements.

7.An imported UV dry system is used to dry the printed matters completely, and an energy-saving dim-out setting is available to save operating cost.

8.Cylinder gears are made of high strength alloy, with robust structure and stable accuracy.

9. The UV lamp with full power and half power automatically switch function, machine off into half light, electricity and prolong lamp using life.

MAIN SPECIFICATIONS:

|

Max Sheet Size |

720 x 1040mm |

|

Min Sheet Size |

320 x 406mm |

|

Max Coating Area |

710 x 1020mm |

|

Paper Thickness |

105-350gsm |

|

Machine speed |

8000 sheets/hr |

|

Total weight |

10000kg |

|

Total power |

67kw |