Ê×Ò³ > PRODUCTS > BOOK MAKING SYSTEM > FOLDING MACHINEZYHD780A-T Electronic Knife Hybrid Folding Machine

ZYHD780A-T ELECTRONIC KNIFE HYBRID FOLDING MACHINE

INTRODUCTION:

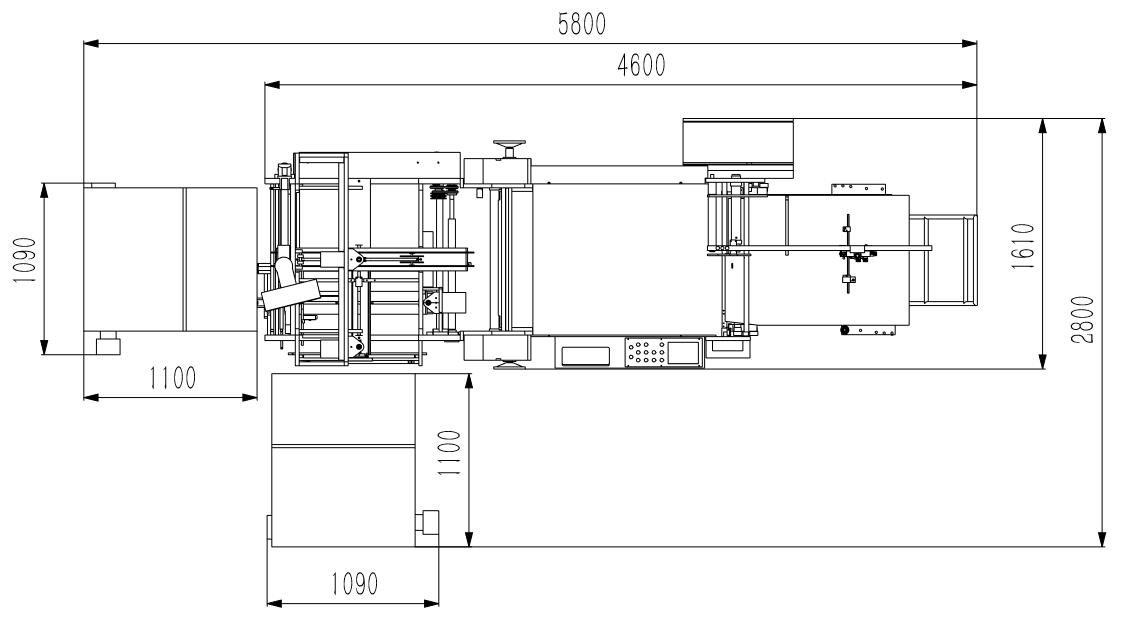

The machine is composed of a paper tray feeding mechanism, 4 fence folds, 3 independent servo-controlled folding knives, and a collating machine. Designed for folding single sheets of paper, including booklets, pamphlets, manuals, letters, etc. The machine features a backpack-style paper-feeding mechanism, 4 fences, and 3 knife hybrid folding. Folds include parallel, accordion, and roll folds for fence-only folding; and vertical mixed quadruple folding for fence and knife hybrid folding. The sheets are collected by a collator. The machine is configured for 4 fence and 3 knife 32-page normal or reverse folding.

MAIN SPECIFICATIONS:

| Max folding paper size | 780x1160 mm |

| Min sheet size |

1-buckle folding: 150x200mm 1-buckle 1-knife folding: 200x300mm 1-buckle 2-knife folding: 300x400mm 1-buckle 3-knife folding: 390x540mm |

| Sheet thickness | 40-200gsm |

| Roll speed range | 650mm |

| Max rotary feeder height | 55-645mm |

| Buckle quantity | 4sets |

| Max vertical folding tines | 3times |

| Roll speed range | 75-210 m/min |

| Max folding knife working frequency | 350stroke/min |

| Folding speed | 210x297parallel one folding27000 sheet/hr 540x780 parallel one folding12000 sheet/hr |

| Power | 7.34kw |

| Weight | 2500kg |

MAIN FEATURES:

1. Intelligent Control System:

Utilizes imported electrical components and control systems, PLC programmable controller, and frequency-variable speed control. The folding knives are precisely controlled by imported servo motors, and maintenance is straightforward.

2. Fault Detection and Protection:

Double-sheet detection in paper feeding and automatic stoppage in case of jams in the fences or knives.

3. High-Speed New Feeder:

The newly developed feeder has a high and stable paper suction frequency.

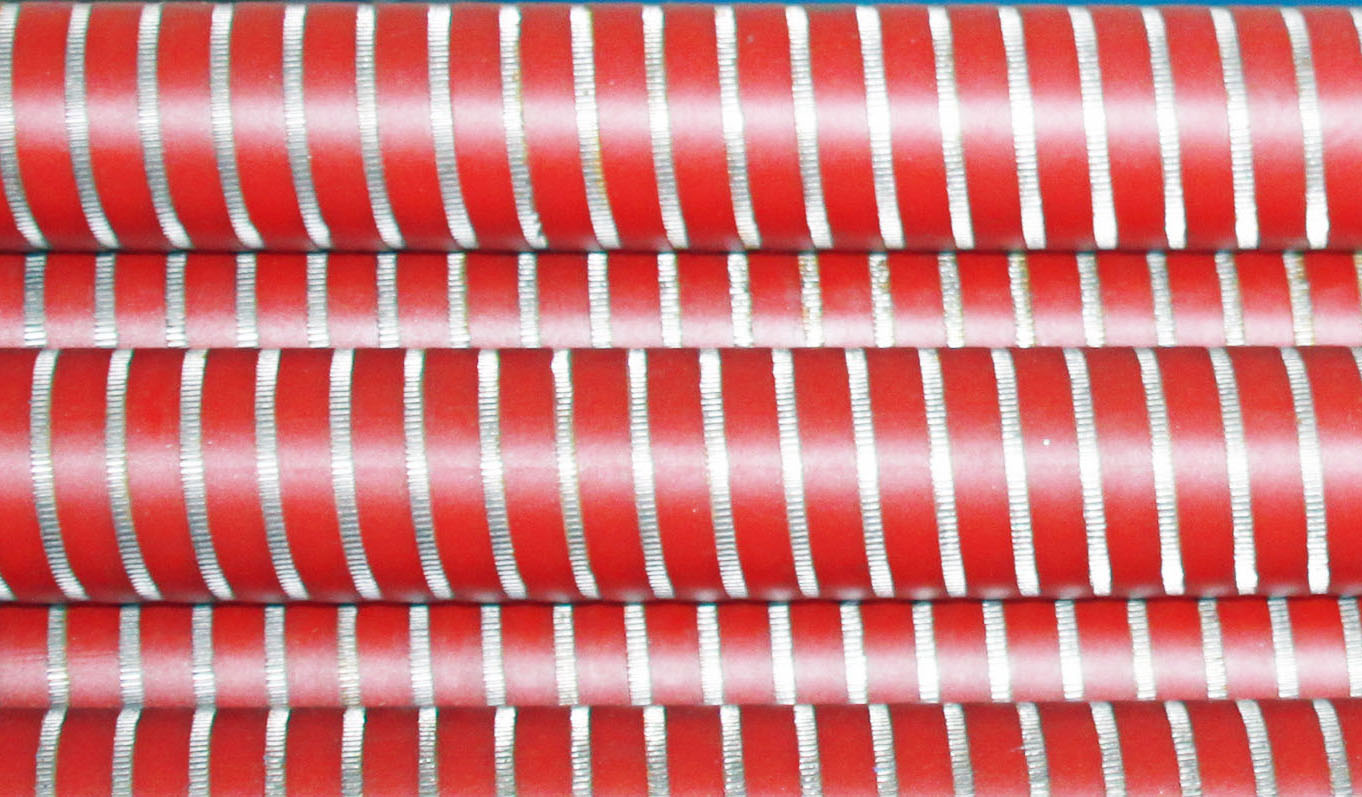

4. Threaded Folding Roller:

The folding rollers are made of imported polyurethane and special material steel, comparable in durability to imported folding rollers. They provide 75% more gripping area than traditional straight rollers.

5. 32-Page Normal and Reverse Folding:

The machine supports both 32-page normal and reverse folding and can resolve layout issues.

6. On-Demand Lubrication:

The central oil lubrication system is equipped with timing and quantification, and low oil pressure triggers an alarm.

7. Paper Transportation:

Three-hole wide polyurethane suction wheels carry the paper to the feeder board, where side alignment takes place.

8. Sheet Separation:

Vacuum suction wheels control the paper feed, with ball rolling for paper alignment.

9. Punching and Creasing:

Optional punching and creasing can be done during the folding process.

10. Counting Function:

Photoelectric switches are used for cumulative and batch counting.

11. Scales and Digital Displays:

Each adjustable part of the machine has corresponding scales and digital displays.

12. Selectable Fence Folding:

The fence board has a swing-type paper turner, allowing for easy selection of fold types like parallel, accordion, and roll folds.

13. Adjustment Data Display:

Scales are set at all machine adjustment points to shorten adjustment time.

14. Automatic Collation:

Upon completion of folding, the booklets are automatically and sequentially collated.

Copyright © 2012 SHM INTERNATIONAL »¦ICP±¸12034060ºÅ-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356