首页 > PRODUCTS > BOOK MAKING SYSTEM > HARD COVER BOOK MACHINEAFM540A/600A Automatic Case Maker

AFM540A/600A AUTOMATIC CASE MAKER

INTRODUCTION:

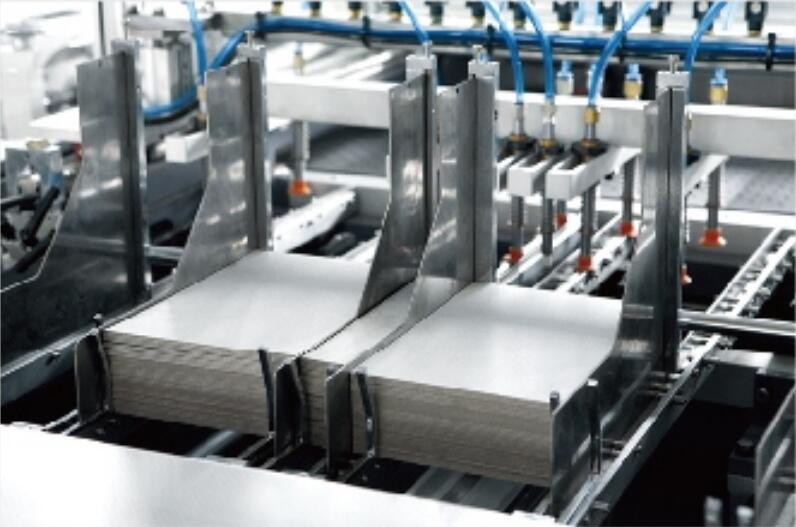

It adopts automatic feeding system for paper, automatic positioning device for cardboard, there are features of accurate, quick positioning, and beautiful finished products. It is used to make perfect book covers, cover of notebook, calendars, hanging calends, files etc.

MAIN FEATURES:

1. The feeder adopts back-push feeding system, which is controlled pneumatically, and its structure is simple and reasonable.

2. The width between stacker and feeding table is adjusted concentrically in the centre. The operation is very easy without tolerance.

3. New designed copper scraper cooperates with the rubber more compactly, effectively avoiding paper winding. And the copper scraper is more durable.

4. Adopt imported ultrasonic paper tester double, featuring in simple operation, to keep two pieces paper from entering into the machine at the same time.

5. The cardboard feeder is controlled by linear guide line and servo motor, its location is correct and quick

6. In the cardborad feeder, the machine can automatically stop when lack of cardboard to reduce the waste.

7. With a power-full sucker motor to keep the paper without any movement.

8. Paper feeding and positioning system adopt imported high-precise phototelectric control device to make the paper and cardboard location more accurate.

9. The folding unit adopts special automatic angle-repair, edge-repair to ensure the qualification of finished products.

10. It adopts PLC control, featuring in simple operation. The troubles are displayed directly on the HML, which helps the operator easily remove them.

11. Optional device: glue viscosity meter.

MAIN SPECIFICATIONS:

|

Model |

AFM540A |

AFM600A |

|

Case size |

Max.540x1000mm Min.100x200mm |

Max.600x1200mm Min.120x220mm |

|

Paper size |

Max.570x1030mm Min.130x230mm |

Max.630x1230mm Min.130x230mm |

|

Inner paper size |

Min.90x190mm |

Min.120x220mm |

|

Paper thickness |

100-300gsm |

100-300gsm |

|

Cardboard thickness |

1-3mm |

1-3mm |

|

Spine size |

≥7mm |

≥7mm |

|

Folding size |

10-18mm |

10-18mm |

|

Cardboard qty. |

6pcs |

6pcs |

|

Precision |

±0.5mm |

±0.5mm |

|

Speed |

≤35pcs/min |

≤35pcs/min |

|

Electric heating power |

10kw |

10kw |

|

Air supply |

30L/min 0.6mpa |

30L/min 0.6mpa |

|

Motor power |

380V 3phase 10kw |

380V 3phase 10kw |

|

Weight |

3500kg |

4500kg |

|

Dimension |

9300x2400x1550mm |

9600x2600x1550mm |

MAIN FEATURES:

1. Line-touch Designed Copper Scraper

The copper scraper cooperates with the glue roller by line-touch design which makes the scraper more durable.

2. Double Paper Detector

Pre-rectifying paper platform is equipped with ultrasonic double paper detector.

3. Cardboard Feeder

Adopt per-stacking non-stop bottom-drawn cardboard feeding device, which impraves the production speed.

PRODUCTION FLOW:

PRODUCT SAMPLE:

Copyright © 2012 SHM INTERNATIONAL 沪ICP备12034060号-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356