Ê×Ò³ > PRODUCTS > BOOK MAKING SYSTEM > HARD COVER BOOK MACHINECM600A Automatic Case Maker

CM600A AUTOMATIC CASE MAKER

INTRODUCTION:

At present, the factory is basically handmade and semi-mechanized production, which requires a large number of labor forces, a large number of labor forces need to carry out human resources management, and these labor forces are some ordinary female workers, their own poor quality, low cultural level, management difficulty, many bosses and managers are also miserable. The automatic cover machine produced by our company has the characteristics of fast production speed, less labor, beautiful finished products and high precision. Products can be widely used in the production of hardcover book cover, notebook, folder, desk calendar, wall calendar, packaging gift box and other fields.

MAIN FEATURES:

1.Paper is automatically glued

2. Automatic transfer of cardboard positioning and fitting

3. Hem on all four sides at once(Folding shaped cover)

4. User-friendly graphical man-machine interface, displayed on all faulty computers

5. The integrated safety cover is designed according to the European CE standard, which is safer and more humane

MAIN SPECIFICATIONS:

| Model | CM600A |

| Paper size | Max.630x1430mm Min.130x230mm |

| Product size | Max.600x1400mm Min.120x220mm |

| Paper thickness | 100-300gsm |

| Cardboard thickness | 1-3mm |

| Center strip size | Min.7mm |

| Folding size | 10-18mm |

| Cardboard qty. | Max.6pcs |

| Precision | ±0.1mm |

| Speed | ≤35pcs/min |

| Air supply | 30L/min 0.6mpa |

| Power | 380V 3phase 12kw |

| Weight | 3900kg |

| Dimension | 9500x2600x1700mm |

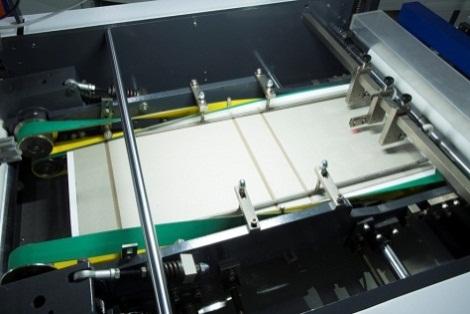

PAPER GLUING PART

Full pneumatic Feeder head: PLC control, simple structure, easy operation, novel design (in the domestic good is the first, is my company's invention patent)

Paper conveyor adopts ultrasonic double paper detection device

Paper correction device, to ensure that the paper glue does not occur deviation

The rubber rollers are all made of polished stainless steel chromium-plated rollers, and the wire contact scraper is more durable

The rubber drum has constant temperature heating, filtering, circulating gluing, and has an automatic mixing device

The valve can be changed quickly, and the rubber roll cleaning takes only 3-5 minutes

CARDBOARD TRANSFER DEPARTMENT

Cardboard conveying adopts bottom extraction structure, in the case of machine without stopping, you can add cardboard at any time

When the cardboard conveying is short, there is an automatic detection device (when several pieces of cardboard are sent at the same time, less than one or several pieces of cardboard, the machine will stop and alarm)

POSITION FITTING PART

The transmission adopts servo motor drive and high-precision photoelectric positioning

The conveyor belt is provided with a high-power suction fan, so that the face paper can be smoothly adsorbed on the conveyor belt

The cardboard conveying is carried by servo motor

The on-line action is controlled by PLC

A pre-pressing roller is provided above the conveyor belt to keep the cardboard and paper fit before folding

FLATTEN PART

The left and right sides of the film base band fold

The folding part is delivered by front and rear split double drive servo motor, synchronous no displacement, no scratch

Angle trimming using motor parts can make the Angle trimming effect more ideal

Using pneumatic structure to wrap edges, can produce special-shaped cover

Multilayer flattening with non-stick Teflon rollers

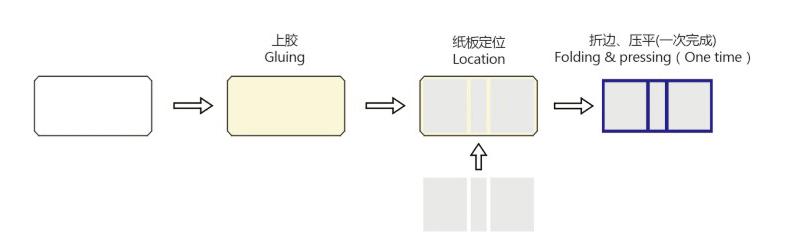

PRODUCTION FLOW:

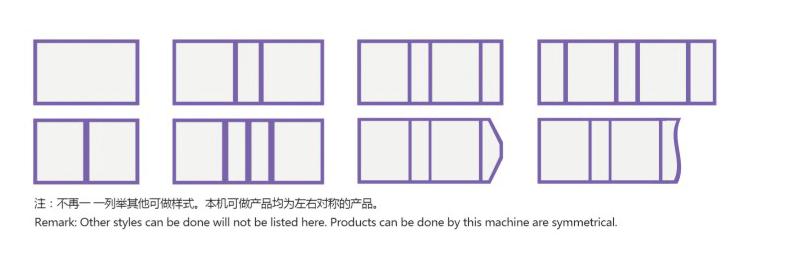

PRODUCT SAMPLE:

Copyright © 2012 SHM INTERNATIONAL »¦ICP±¸12034060ºÅ-3

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356