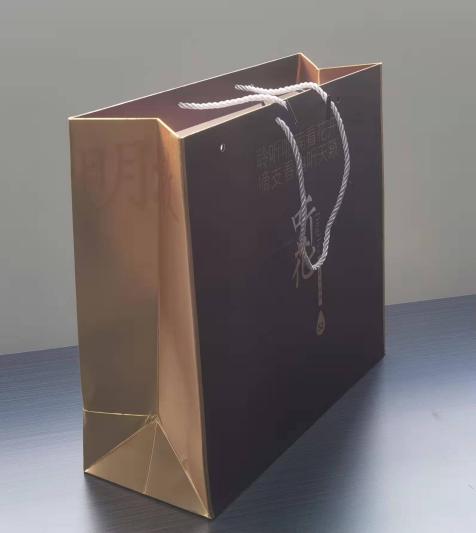

首页 > PRODUCTS > PAPER PRODUCT SYSTEM > SHOPPING BAG MACHINED450 Automatic paper Bag Stringing Machine

D450 AUTOMATIC PAPER BAG STRINGING MACHINE

|

Model

|

D450

|

|

Bag width

|

190-450mm

|

|

Bag height

|

190-450mm

|

|

Bag weight

|

180-300gsm

|

|

Distance between holes in the rope

|

75-140mm

|

|

Rope hole size

|

Φ4mm, Φ5mm, Φ6mm

|

|

Rope length

|

320-430mm

|

|

Speed

|

35-40pcs/min

|

|

Air compression

|

6-8bar

|

|

Apply rope material

|

Cotton rope, three woven rope, silk rope, etc

|

|

Power

|

Max. 12kw

|

|

Weight

|

2700kg

|

|

Dimension

|

4260x2150x2150mm

|

In the case that the machine does not stop, it can realize uninterrupted feeding and improve the production efficiency of the machine.

2. Vacuum Bag take system

Using the vacuum principle, the suction nozzle is attached to the paper bag to absorb the paper bag. And put the paper bag into the transfer station.

Put its paper bag into the punching station.

3. Chain transfer station

The rotation of the gear is controlled by the motor to drive the chain, so that the station rotates.

4. Paper bag punching system.

It is conveyed by the chain to the punching station, and the inductive switch detects the position of the bag.The cylinder drives the needle rod to punch the bag.

5. Wrist plastic buckle hemming

The cam is driven by the private server motor to drive the mold, and the paper bag is punched and the wrist plastic sheet is rolled at the same time.

6. Rope take and cut module

The wrist rope wrapped with plastic sheet will be clamped by the rope clamping cylinder and pulled to the required length. And push the scissors to cut.

7. Rope insertion module

Hand the trimmed rope to the Insert Rope module. The cord clip will pick up the plastic pieces at both ends. Insert the punched position of the paper bag.

8. Extract rope clip

increase the rope insertion depth.Re-insertion of the rope is to move the rope up and down through the private server motor to extract the rope into the bag.

9. Private server control driver, and circuit control

Add: RM1616, No. 2993, Gong He Xin Rd. Shanghai, 200072 P.R. China

Tel: 0086-21-36562322 Fax: 0086-21-33250356